What is Deionization & Why Should I Be Using It?

- News

- 03 Jan, 2019

Deionization (DI) is a very convenient and cost-effective water filtration process for producing highly purified water on demand for aquarium or hydroponic use. By definition, deionization, often called DI for short, is the removal of all ionized minerals and salts (both organic and inorganic) from water through the process of ion exchange. Because most non-particulate water impurities are dissolved salts, deionization produces high purity water that is generally similar to distilled water, but compared to distillation deionization is much faster, less energy-intensive, and more cost-effective. In addition, it is an on-demand process that supplies large amounts of highly purified water as needed. Deionization removes total dissolved solids (TDS) from water using ion exchange resins, controlling the electric charge of ions in the water to remove the TDS. Much like a positively charge magnet will attract a negatively charged magnet; DI resins attract non-water ions and replace them with water ions, producing a more purified water.

How Does Ion Exchange Resin Work?

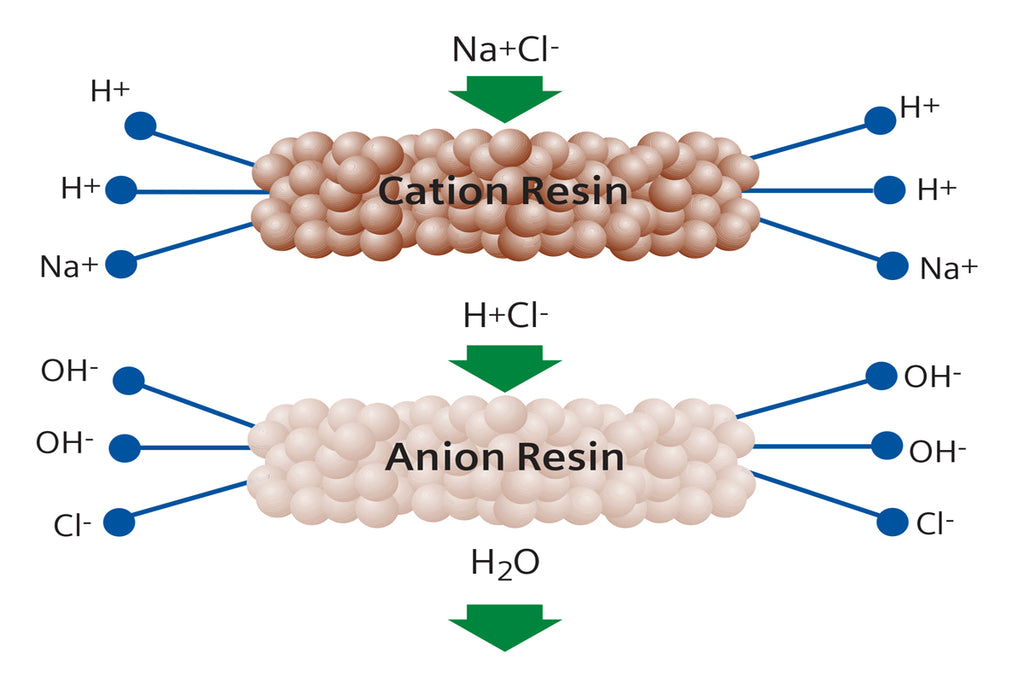

The deionization process uses two resins that have opposite charges – the cationic (negative) and the anionic (positive). Cationic resin contains negatively charged sulfonic acid groups, pre-charged with hydrogen ions. This resin attracts the positively charged ions in the water (Calcium, Magnesium, Sodium, etc.) and releases an equivalent amount of hydrogen (H+) ions. Anionic resin contains positively charged ammonium groups. It is pre-charged with hydroxide ions. This resin attracts negatively charged ions (Fluoride, Chloride, Sulfate, etc.) and releases an equivalent amount of hydroxide (OH-). The hydrogen and hydroxide ions then combine to form water. (H+ + OH- = HOH or H2O.) The best DI resin to use is the color changing mixed bed type that changes color from blue/green to amber as the resin is exhausted. Our standard 10-inch DI filter cartridge is opaque so you can see when the resin is depleted and it’s time to replace the cartridge. The 10-inch cartridge is also refillable and we offer our color changing mixed bed resin in three sizes, which is a more economical way to refill your cartridges if you’re a DIY’er.

If you’re not using DI resin in your reverse osmosis system you should be. Adding the deionization process to a 3-stage RO system is again easily done using a standard 10-inch DI filter cartridge filled with color changing mixed bed DI resin. The DI cartridge is used in the final stage of the RO system, after the sediment pre-filter, carbon block cartridge and membrane. Unscrew the last housing in your RO system and install the cartridge – it’s that simple. In a 4-stage RO system the same cartridge is also used in the final stage. If all of your housings have cartridges installed then you can easily add DI to your system using our DI cartridges that attach to the membrane housing on your RO system. For our RO Buddie systems use the 21-CI Inline cartridge that also attaches with clips to the membrane housing. As with most of types of filtration, a single deionization cycle may not remove all the TDS in your supply water, so running the DI water through a second DI cycle will provide additional purification. Dual-stage canister systems can be added for additional DI purification. These are available with DI cartridges included, and are easily plumbed into any existing RO system.

How Long Does DI Resin Last?

Over time positive and negative contaminants in the water displace the active hydrogen and hydroxyl molecules in the ion exchange resin and the resin loses its ability to remove contaminants, it becomes exhausted. The lifespan of a DI filter cartridge can vary greatly with the quality of the supply water used and the RO system configuration. If the RO system pre-filter sediment cartridge, carbon block cartridge or membrane cartridge are in need of replacement, then they are not filtering properly, and more TDS are being sent to the DI cartridge which will exhaust the resin more quickly. Here’s a simple example to understand why replacing your membrane and pre-filter cartridges every 12 months or 3000 gallons will greatly extend the life of the DI resin: when comparing a 10 TDS water supply with a 20 TDS water supply, the DI resin needed to filter the water would be used up TWICE as fast with the 20 TDS water supply compared to the 10 TDS water supply.

Lastly, it is important to test the filtered water coming from your RO system with a TDS meter after each cycle to verify the effectiveness of your DI filter cartridge. Compared with other filtration methods, DI resin has a relatively short life and once it is depleted the TDS level of the filtered water will rise quickly, so we recommend you check your filtered water regularly using a TDS meter.